Assembly & Maintenance

Assembly

High pressure tube

High pressure connections on the tube-side consist of an outer cone, which works as the sealing surface. Beside this there is a left-handed thread profile on the tube-side of the connection, which is needed to fix the collar. The opposite side of the connection the so-called fitting consists of an inner cone with a 2-5° bigger angle and an inner thread to fix the gland.

Instructions for pipe processing can be found here.

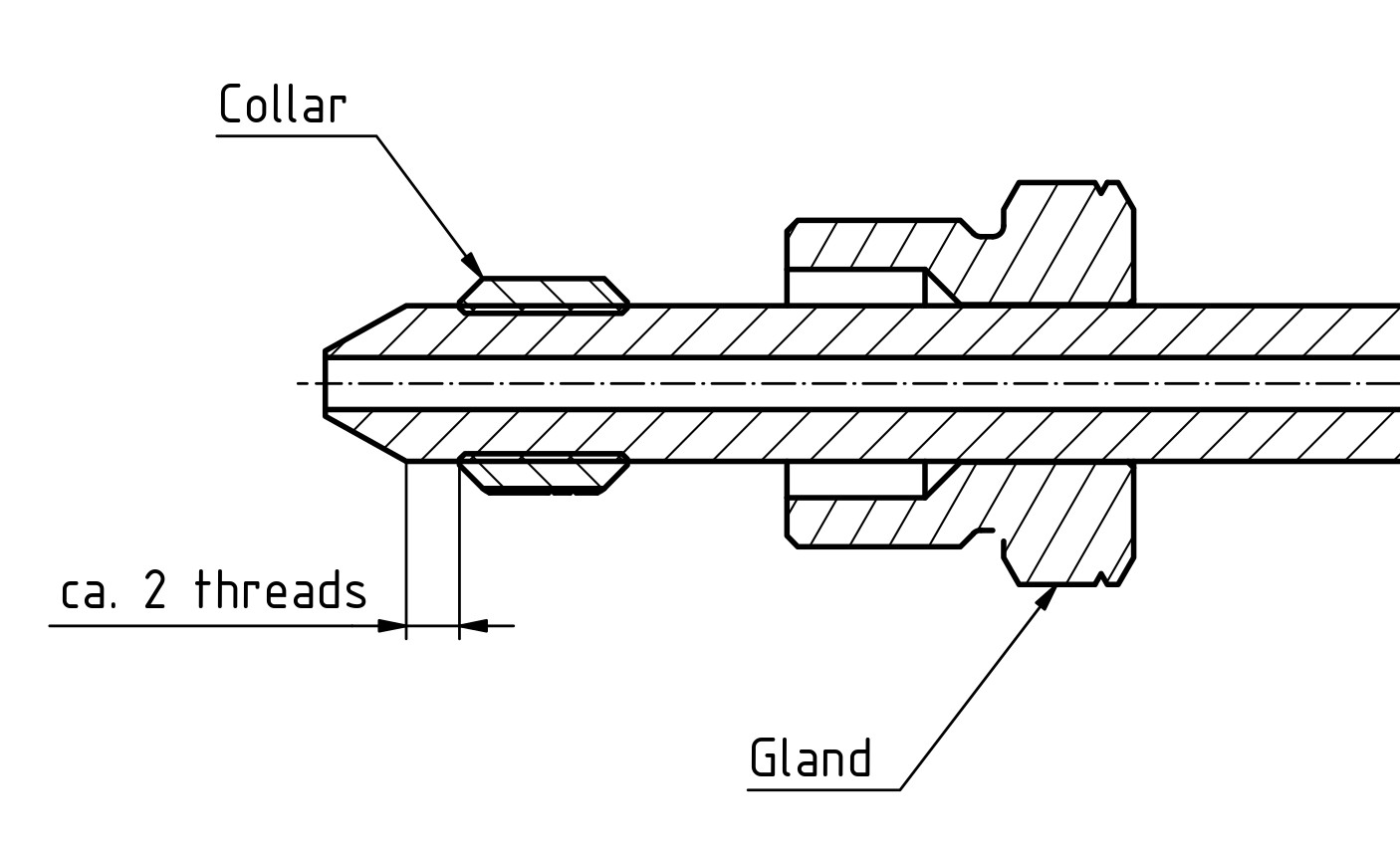

When assembling high pressure tubes, it is important to first push the gland on the tube and then to screw the collar (attention: left-hand thread) onto the tube so that about 2 threads to the cone remain free (Fig. 1).

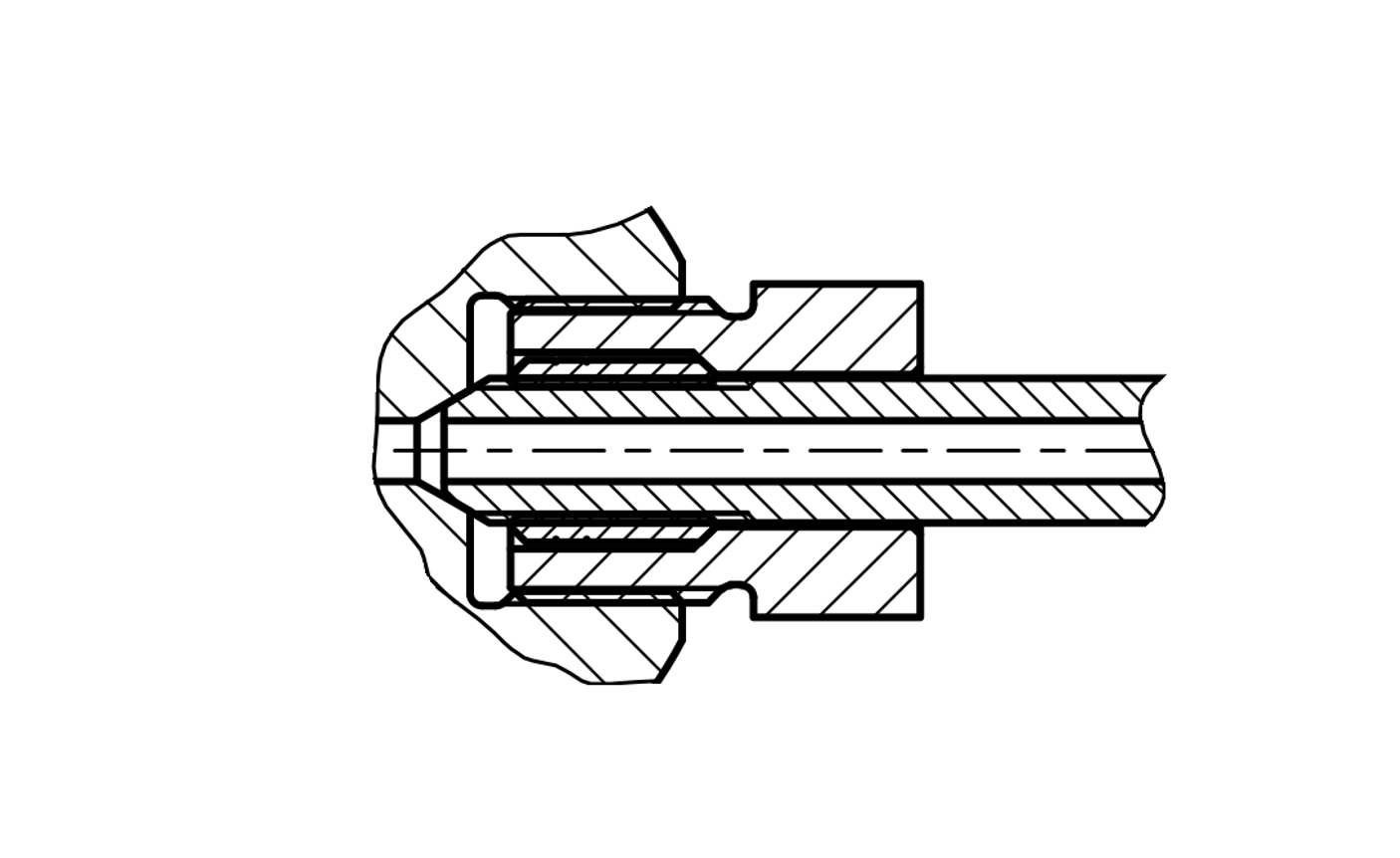

This has the effect that the hole thread length of the gland is used (Fig. 2) and the relief holes remain free. Only in this way is a safe operation possible.

Figure 1: Assembly of the collar

The gland is now screwed into the fitting and given the specified tightening torque (see table 1).

Figure 2: Assembly of the gland

| Operating Pressure PN [bar] | Tube outer diameter | Collar SW | GlandSW |

Tightening Torque Glands |

| 2500 | 9/16" |

19 |

32 |

... |

4200 |

... | |||

| 1/4" | 9 | 17 | ... | |

| 3/8" | 12 | 22 | ... | |

| 7000 | 1/4" | 9 | 17 | ... |

| 10000 | 3/8" | 12 | 22 | ... |

Table 1: Width across flats and the specified tightening torque for the glands and collars

If the pipe should be bent, it must be ensured that the shorter bending radius will not exceed 5 times of the tube outer diameter otherwise the durability of the tube will decrease.

Plugs

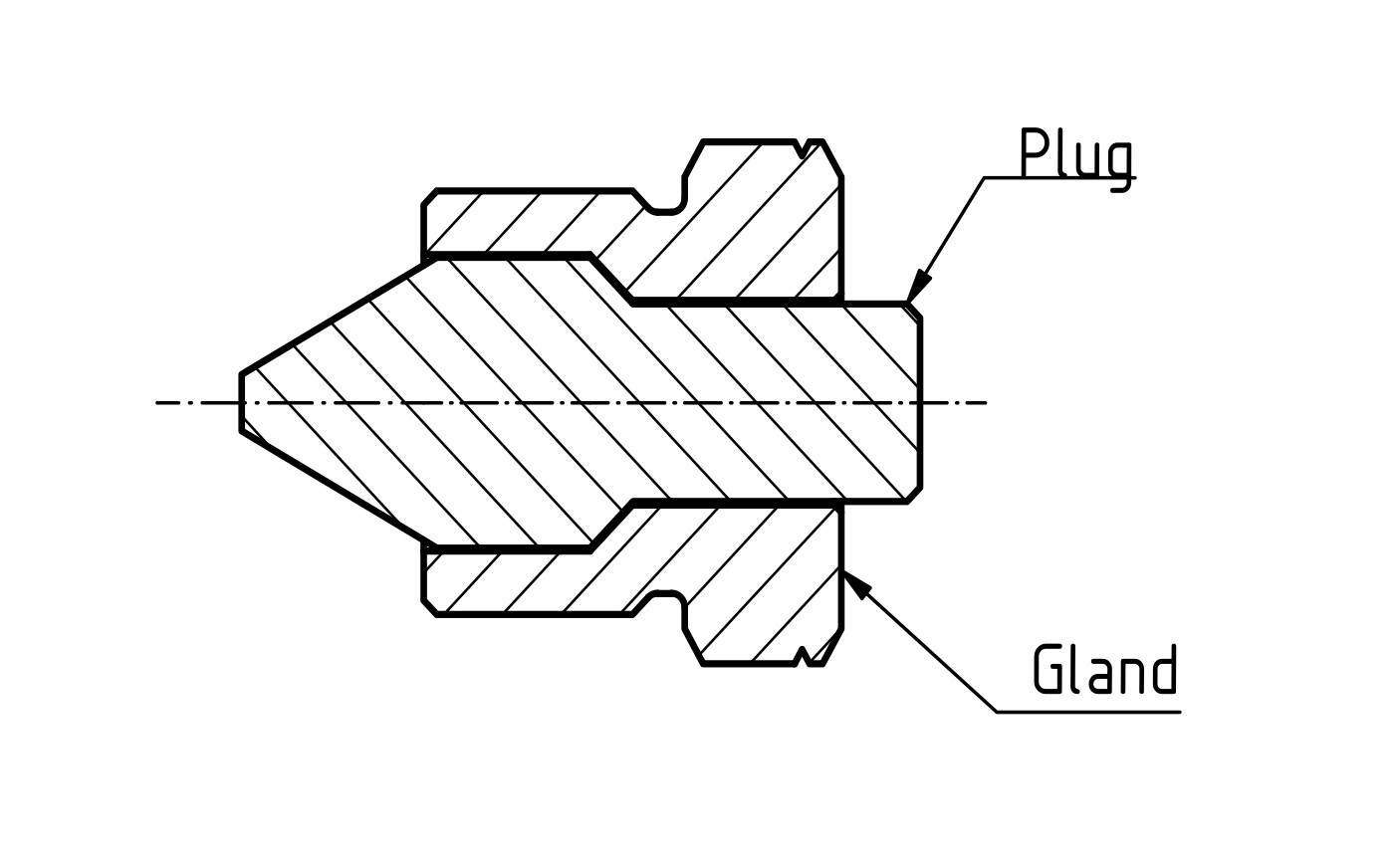

Plugs (Fig. 3) are used for a pressure-tight sealing of the high-pressure connections. For assembly, the plug is insert into the gland and then screwed into the fitting with a specified tightening torque. A pressure ring is not necessary.

Figure 3: Plug in the gland

Maintenance

In case that the high-pressure connection is installed correctly but is not completely tight, the inner and outer cone of the connection can be reworked with the baromax reseating tool or the baromax coning tool.

Did you forget your password?

Did you forget your password?